Cylinder Head Replacement Project – Machining

Cylinder Head Replacement Project – Machining This is a summary of the 13-month project to replace the damaged and unrepairable Edmunds aluminum cylinders on my 1960 Willys Super Hurricane engine. For more details about the project, visit my build thread, 1960 Willys Utility Wagon – Be Careful of Big Ideas on the Old Willys Forum. Figure 1 is a rendering of the Solidworks model. The model was sent to a company called ExOne for casting. They 3D printed the mold components. Here is a link that shows their fluid flow and solidification modeling process and here is a link to the cylinder head casting process. Figure 2 shows the casting on the Clausing 8520 milling machine, as it looked when I received it from ExOne. Due to the mill’s limited travel in the x-y directions, it required four setups to reach all the features. In this first operation,…

1960 Willys Utility Wagon – An Observation

When I am out and about with my 1960 Willys Utility Wagon, it is not unusual for people to ask “What is that?” or make the comment “I have never seen one of those.” The question I then ask myself is “Why don’t people know about Willys Utility Wagons?” If I were driving a 1969 Camaro most people would identify it, or at least recognize it as a ‘60s muscle car. So, what is the issue with Willys wagons? Contents1 Uniqueness2 Rarity3 Collectibility4 Another Look at Rarity5 Simply Unremarkable6 Brand Recognition Uniqueness The Willys Utility Wagon’s versatility and capability were unique for that era. I am not aware of any other US auto manufacturer that produced a four-wheel drive, off-road vehicle, with room for up to seven passengers. Wikipedia states that the Willys wagon “[is] the ancestor of all sport utility vehicles.” If so, why isn’t everyone scrambling to own…

Willys Utility Wagon – Unique, Rare, Collectible, or Simply Unremarkable

Contents1 My Experience2 Uniqueness3 Rarity4 Collectibility5 Another Look at Rarity6 Simply Unremarkable7 Brand Recognition My Experience When I’m out and about with my 1960 Willys Utility Wagon, it is not unusual for people to ask “What is that?” or make the comment “I’ve never seen one of those.” I then ask myself “Why don’t people know about Willys Utility Wagons?” If I were driving a 1969 Camaro most people would identify it as a Chevrolet, or at least recognize it as a ‘60s muscle car. So, what is the issue with Willys wagons? Uniqueness The Willys Utility Wagon’s versatility and capability were unique for that era. I’m not aware of any other US auto manufacturer that produced a four-wheel drive, off-road vehicle, with room for up to seven passengers. Wikipedia states that the Willys wagon “[is] the ancestor of all sport utility vehicles.” If so, why isn’t everyone scrambling to…

What Would it Take to Keep Your Original Engine

It Does Not Make Enough Power Recently, I overheard someone asking a question about replacing the F4-134 in his 1952 pickup. I began to wonder what it would take for most of us to leave the stock engine in place. The usual reason that I hear when asking why the engine was replaced is that it did not have enough power. I agree that the L4-134 Go Devil, L6-148 Lightning, F4-134 Hurricane, L6-161 Lightning, F6-161 Hurricane, L6-226 Super Hurricane or the 6-230 Tornado are not high performance engines, or even considered to be of moderate performance. Engine Performance Specifications My understanding is that any engine producing more that 1.0 HP per cubic inch is considered to be high performance. The stock Willys engines are rated at about 0.5 HP per cubic inch. The road from 0.5 to 1.0 and beyond is not a straight one – it takes an ever…

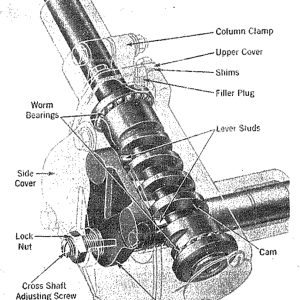

Ross TL-12 Steering Gear

Ross TL-12 Steering Gear Pitman Arm to Sector Shaft Installation and Development of Assembly Specifications VEHICLE: 1960 WILLYS UTILITY WAGON SN: 54168 50039 Contents1 Abstract2 Introduction3 Investigation4 Original Pitman Arm to Original Sector Shaft Fit-up5 NOS Pitman Arm to Original Sector Shaft Fit-up6 Original Pitman Arm to NOS Sector Shaft Fit-up7 NOS Pitman Arm to NOS Sector Shaft Fit-up8 Pitman Arm Installation Specifications9 Solution10 Conclusion Abstract The pitman arm to sector shaft fit is not usually checked before the steering gear is installed in the vehicle. Out of tolerance parts will not be noticed until it is time to install the pitman arm on the sector shaft. Since design dimensional data is not available, an alternative method must be used to identify out of tolerance features. This paper presents a method to visually identify part deficiencies and to hand-fit out of…

Definition of an Original or Stock Vehicle

Making the decision to improve the looks and performance of my Willys was easy; deciding how to do it was the hard part. My first thoughts were to restore the vehicle but I realized that I didn’t really understand what that meant. I realized that I had just encountered my first problem; the need to figure out what it was that I was trying to do with my vehicle. Was it a restoration? Was I fixing it up? Or was I modifying the vehicle? Certainly there is no lack of debate on this topic. To put the issue to rest, for me at least, I did some research to define categories of work that I could live with. The most influential information came from the Antique Automobile Club of America’s (AACA) 2016 Official Judging Guidelines; Section 1, Paragraph III – General Policy. Following is what I came up with: Original…

WINDOW GLASS REPLACEMENT CONSIDERATIONS FOR 1960 WILLYS UTILITY WAGON

Contents1 THE USUAL SUPPLIERS2 OTHER CHOICES3 WINDOWS IN MY 1960 UTILITY WAGON; SN 5416850039 (2,677 OF 8,968 BUILT IN 1960) 4 DECODING THE LOF GLASS MONOGRAM5 SUMMARY6 WINDOW GLASS SUPPLIERS THE USUAL SUPPLIERS My project was ready for window glass so I went to a couple of the usual sources; Walck’s 4 Wheel Drive and Kaiser Willys Auto Supply, INC to compare prices. The cost difference to purchase the necessary 14 windows individually was less than three percent, with Walck’s being the less expensive. Each supplier offers a kit that includes the 14-piece glass set for considerably less cost. However, Walck’s kit cost is about 12% less that the KW kit. OTHER CHOICES Before ordering I decided to look into a couple of the many alternative window glass sources. By chance I came across Sanders Reproduction Glass. They list our vehicles and have a very easy to use on-line ordering and cost estimating tool. …